Beddeleem Circular

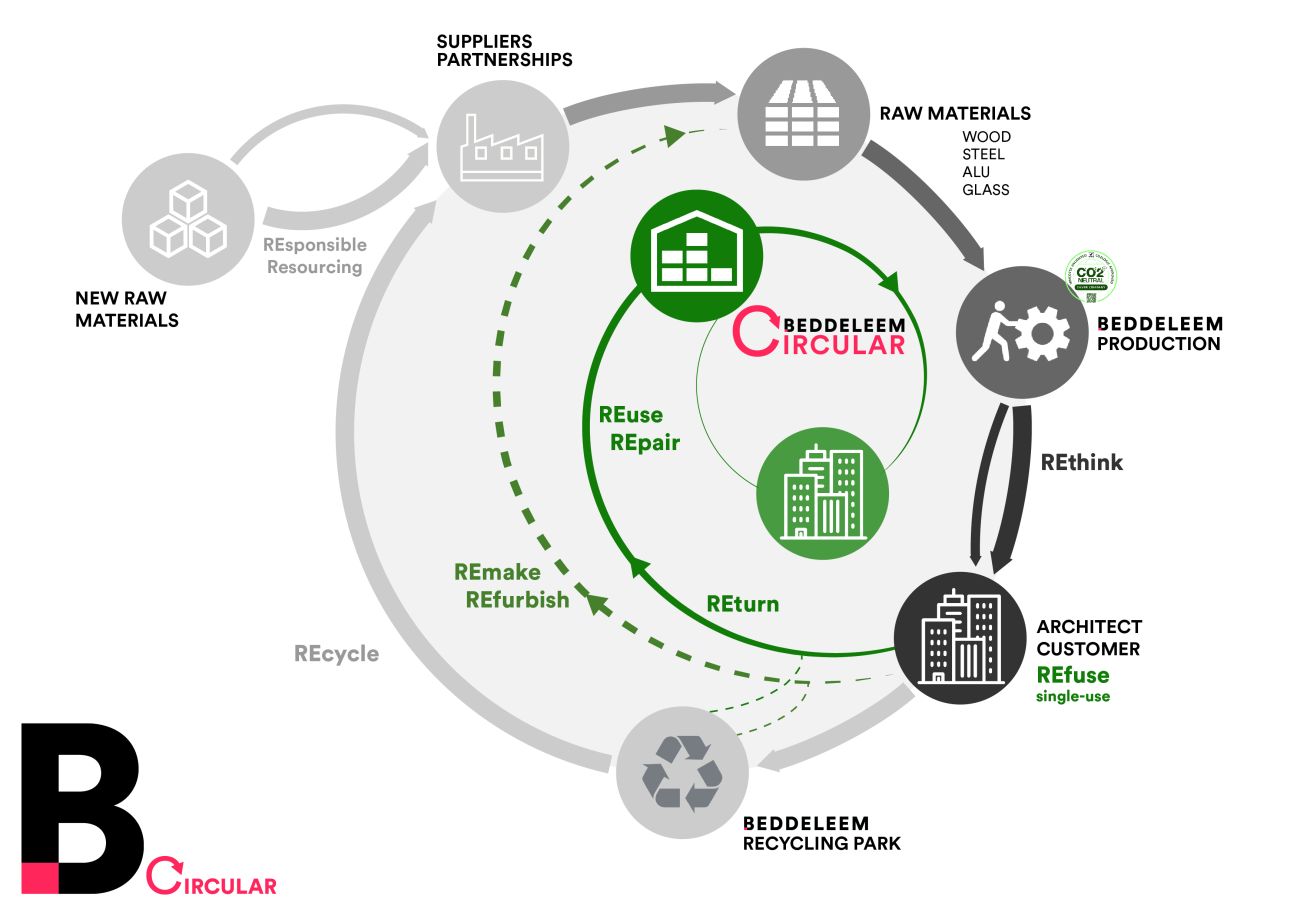

Make use of our Beddeleem Circular range. It includes relocatable partitions and doors that already have a lifetime behind them. Through Urban Mining, they were picked from renovation or demolition works. Since November 2021, we have a separate storage location where we temporarily store them in order to give them a second (or third, or fourth,...) life in another project.

Our systems are designed circularly, proof of this are our CERFF and Cradle to Cradle Certified ® certifications and the numerous projects where the partitions have already been moved in a new layout. They can be reused as a whole (profiles, finishes, windows, doors, etc.) or the elements can be exchanged or they can be supplemented with new elements from our collection.

With the Beddeleem Circular programme, we took the initiative and started to extend the actual lifespan of our products even more. This avoids unnecessary energy for conversion to other products or recycling. Together, we reduce the impact of your project and keep the circle as small as possible.

With our after-sales service, we have been demounting and reassembling our relocatable partitions for more than 30 years. So at Beddeleem, we have known about circularity for a long time. Our in-house study bureau analyses the available material and the new layout. So we have the knowledge and know-how to put that puzzle together.

Materials databases are a next step. Read more about our Madaster Max partnership.

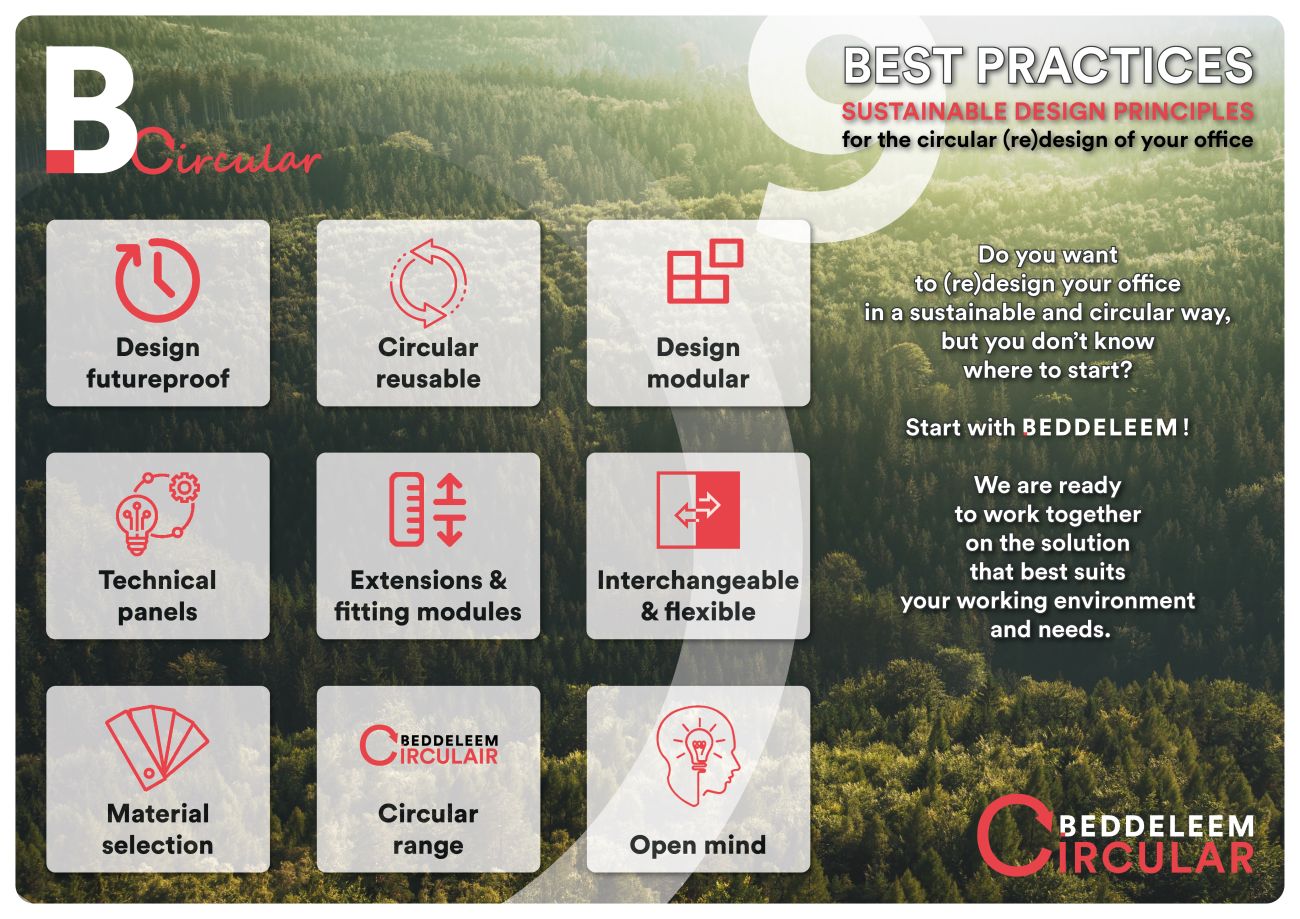

Below, we like to give you 9 Best Practices as well - Sustainable design principles for the circular (re)design of your office.

Would you like to reduce the impact of your renovation or conversion project? Are there existing Beddeleem system partitions on your site? We will make a project-specific analysis and discuss options together.

Project Classified Cycling - Chocolate factory | Beddeleem

Project HUB Brussels | Beddeleem

Critical Care Expo - De Singel - co-produced by Beddeleem Circular | Beddeleem